Products >>>

.

Vacuum Tray Dryers

.

Vacuum Tray Dryer is engineered using mild steel components, standard pressure vessels and tabular steam coils. These dryers are equipped with built-in temperature, networking controllers, input and output chambers. The capacity of these vacuum tray dryers are 12 96 trays segregated into different shelves. Our products are known for their performance in drying various products.

Type : | Contineous, Batch and Semi-Batch Reactors |

Material : | Stainless Steel and Mild Steel |

Features :

- Sturdy welded external chamber reinforcement ensures maximum operating protection and dependability

- under full vacuum operation.

- Hollow pad type heating shelves baffled for essential heat transfer

- All shelf to manifold connectors are located outside the dryer chamber to inhibit product contamination

- Validation ports and nitrogen purge nozzles

- Fluid heating and circulating systems either steam or electrically heated, with PLC based process

- control possible

- Coated with Red Oxide Paint

- Proper Heating

- Adjustable Damper

.

Chemical Reactors

.

Chemical Reactor is a vessel designed to contain chemical reactions. An industrial reactor is a complex chemical device in which heat transfer, mass transfer, diffusion and friction may occur along with chemical with the provisions of safety and controls.,The design of a chemical reactor Is the most important factor in determining the overall process economics, as all chemical processes are centered in a chemical reactor. Various designs of chemical reactors are available to suite the various process requirements.

We Provide Our Clients High Quality Reactors That Find Wide Usage In Chemical Pharmaceutical, Food, And Beverage Industries. The Entire Range Is Manufactured Using Innovative Techniques Of Producation For Conformaing Industrial Standards. Known ForHighDurability,efficiency,andTemperature, These Are Avaliable Invarious Designs As Per the needs Of Clients. Our Wide Range Of Reactors IncludesThe Following:

- AGITATION REACTORS

- HYDROGENATORS

- HVD'S

- DISPERSERS

Type : | Contineous, Batch and Semi-Batch Reactors |

Material : | Stainless Steel and Mild Steel |

.

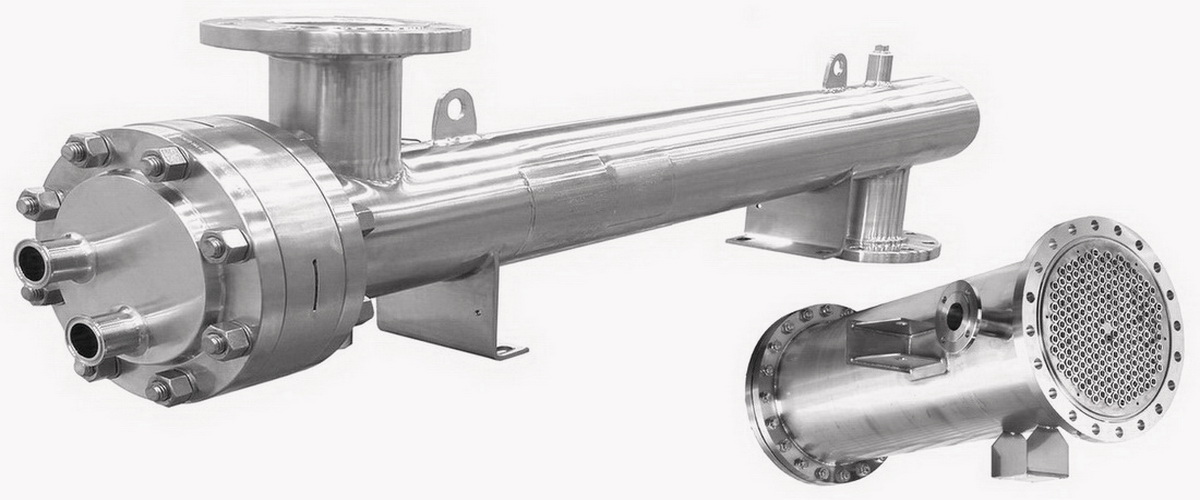

Heat Exchangers

.

Heat Exchangers Offered By Us Are Highly Efficient In Transferring Heat From One Fiuid To

Another. These Are Sturdy In Construction, Can Withstand Maximum Stress And Are Highly Resistan To Heat, Abrasion & Corrosion. Due To These Attributes, This Range Of Heat Exchanger Is Ideally used In space heating, Refrigeration, Air Conditioning, Power Plants , Chemical Plants, Petroleum Refiners And Natural Gas Processing. We Offer Shell And Tube Type Exchangers. Which Are Available In Horizontal And Vertical Designs

Type : | Horizontal and Vertical Axis |

Material : | Stainless Steel and Mild Steel |

.

Fermenters

.

Fermenter is a vessel that maintains optimum environment for the development of significant microorganism used in large scale fermentation process and the commercial production of products like Alcoholic beverages, Enzymes, Antibiotics, Organic acids etc. The fermenter aims to produce biological product like vaccines and hormones, it is necessary to monitor and control the different parameters like external and internal mass transfer, heat transfer, fluid velocity, shear stress, agitation speed, aeration rate, cooling rate or heating intensity, and the feeding rate, nutrients, base or acid valve.

We study the fermentation process, and manufacture to suite the application and techniques are simply defined as fermentation technology. The fermenter or bioreactor are defined as the heart of fermentation process within this fermenter many reactions and activities occur.

Type : | Agitation System and Aeration System |

Material : | Stainless Steel and Mild Steel |

Features :

- Neutralizes the acidic environment and maintains the required pH

- Measure the level of medium

- Measure and monitor temperature change in the medium during the fermentation process

- Introduce sterile air or oxygen to the media in the aerobic fermentation process

- Continuous stirring of media, distribution of the oxygen throughout the system and prevent cells from settling down

- Regulate and limit the flow of liquids and gases

.

Filters ( Nutche, Leaf, Basket and Candy Type )

.

Filters of various types are the closed vessels designed to separate liquid and solid by filtration under vacuum or pressure. The closed system ensures odourless contamination free and non-polluting working conditions maintaining product purity and hygiene. Agitated Nutsche Filters are extensively used in pharmaceuticals, agro chemical, food and chemical industries, Nutsche Filters are available in lab type through pilot plant and production scale, in volumes ranging from 40 Its to 6000 ltrs.

Material : | Stainless Steel |

.

Receivers & Storage Tanks

.

Receivers & Storage Tanks are the devices used for the store material like chemicals, organic liquids, non organic liquids, vapors and can be found in many industries. Most storage tanks are designed and built to fulfil the requirements of the various sectors.. Storage tanks can have different sizes, They are generally installed inside containment basins in order to contain spills in case of rupture of the tank. These storage tanks primarily used in chemical, pharaceuticals and petrolium industries.

We Offer An Exclusive Range Of Receivers, Which Is known For High Performance, Low Maintenance, Rust Proof Features, And Low Maintenance. Available In Different Sizes And Dimensions To Suit The Various Flow Rates, These Are Used In Various Industrial Applications. We Also Offer Customized Designs As Per Specifications Laid Down By Clients For Varied Requirements. We Are Engaged In Providing Quality Storage Tanks,that Are Fabricated Precisely To Minimize The Inconvenience For Easy Usage.these Are Ideally Used For Storing Of Solvents, Chemicals,

Material : | Stainless Steel |

.

Rotary Cone Vacuum Dryers

.

We offer a comprehensive range of Double Cone Rotary Vacuum Dryers that is widely used for vacuum drying of heat sensitive materials. The main structure of the dryer is provided with external jacket for heating, drying of powders & granules under vacuum. Heating is these are done by hot water and steam due to heat sensitive nature of material. These are provided with mechanical seal, rotary seal, solid separator cyclone, inert gas purging & heavy-duty direct drive.

Specification : MOC: S.S 316, S.S 304, Hastelloy, rubber lining, FRP lining, teflon lining

Capacity : | 150 - 5000 L |

Models : | Cantilever, double shaft, GMP & cGMP models |

Material : | Stainless Steel |

.

Box Condensers

.

Box condenser is a condensing equipment or unit used to condense a substance from the state of its gaseous to liquid, by cooling it. In so doing, the latent heat is transferred to the surrounding environment, and given up by the substance.Condensers can be made according to various designs, and come in many sizes ranging from rather small to very large Like a refrigerator uses a condenser to get rid of extraction of heat from the internal to the outside air. Condensers are used in air conditioning, industrial chemical processes such as distillation, steam power plants and other heat-exchange systems. Use of cooling water or surrounding air as the coolant is common in many condensers

Features :

- High efficiency

- 2 in 1 primary & secondary cold

- Good solvent recovery

- More cooling effect compare to the shell & tube condenser

Material : | Stainless Steel |

.

3 Point Model Centrifuges

.

Our centrifuges are of the most modern design, of sturdy construction;

provide rapid

acceleration, with low

current consumption and powerful efficient braking. The centrifuges can be made fully automatic with

the help of AC inverter variable speed drive, programmable

logic Controller and automated valves

.

Solvent Recovery Systems / Distillation Column

.

Distillation Is the separation of solvents by difference of boiling points to produce reusable, purified solvent. distillation systems generally include multiple stage, vapor liquid present, then the process may also include an evaporation step that vaporizes the volatile compounds, so the solids can be removed.

Solvent Recovery Distillation may be via continuous or batch operation. In either case, the configuration must be adapted to the particular vapor-liquid equilibrium (vle) characteristics of all combinations of all chemical compounds found in the application

.

Agitated Nutche Filters cum Dryers

.

Agitated Nutche filters are used widely in the production processes of pharmaceutical, chemical and laboratory industries, among others. They are manufactured as agitated Nutche filter dryers (ANFD'S) for the filtration and drying in the same unit of active pharmaceutical ingredients (API) and chemical compounds

It is a filtration technique used in applications such as dye, paint, and pharmaceutical production and waste water treatment. Safety requirements and environmental concerns due to solvent evaporation led to the development of this type of filter wherein filtration under vacuum or pressure can be carried out in closed vessels and solids can be discharged straightaway into a drier.

Advantages :

- Vacuum or pressure filtration possible.

- Inert gas atmosphere can be maintained.

- Minimal contamination of the cake.

- Very high solvent recovery.

- Considerable saving in manpower.

- Solvents are in closed systems, so no toxic vapors are let off in the atmosphere.

- Personal safety is maintained and heat transfer surfaces can be provided to maintain filtration

.

.

.

.

.

.